Sources of light through time.

Fuels played an important role for the illumination of lighthouses.

In antiquity, when a known boat arrived or fishermen returned, the population used a brazier. Outside of these times, there was no lighting.

They used what they had at their disposal. It was mostly wood, but in some places it was a rare commodity.

The fire was placed on a open fire or placed in perforated iron baskets. One can see a copy in Mornac (see photo) and a second copy in Skagen (Jütland - Denmark).

The wood was also replaced by what they had on hand, such as coal and various greases. All of this had a cost that had to be paid by the community.

Coal consumption was considerable and very expensive. At the first Ailly lighthouse, no less than 600 kg of coal per night is burned and must be climbed.

And all for poor performance.

Vegetable and mineral oils.

The problems are multiple. The amount of coal to climb makes the work difficult. The number of companies is not easy to manage. The fires are not lit regularly. The cost of coal is excessive, it must sometimes be imported from Scotland or Spain. Not to mention the storage space.

Chassiron Lighthouse Museum.

The "Compagnie Tourville-Sangrain" undertook to illuminate cities including the city of Paris. They are responsible for the oil supply, ignition and maintenance.

This solution will be considered for lighthouses. One company that looks after everything with oil that is cheaper than coal.

The first street lamp was installed in Sète in 1770. It gives full satisfaction.

The other lighthouses will follow and the transformations will be carried out. The "Compagnie Tourville-Sangrain" will have a contract for all the lighthouses.

So many advantages except one, the range of the fire is not always up to expectations.

Why?

It burns oils that are made on site with what you find. For example whale oil, fish oil, vegetable oil … Often mixtures that cause a lot of smoke, low lighting and too short duration.

Finally, it was decided to use only canola oil.

In parallel with this evolution, glass lanterns were placed on the towers. Wind and rain do not improve the stability of the fire. These lanterns have a dome with a chimney.

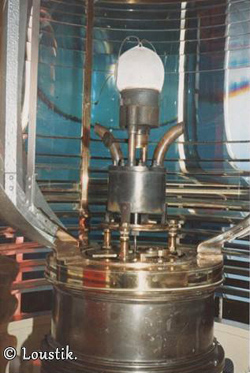

Burner large model.

The street lights are equipped with parabolic reflectors. The installed fixtures have several reflectors with as many burners.

In 1782, the company installed 80 reflectors in Cordouan lighthouse. The beam is still too low. Lack of calculation because the wicks are not always placed in the focus and the parables are not perfect. This problem is solved by a more serious fabrication. Also note that we will increase the number of wicks per dish.

But the number of wicks will further increase oil consumption and require an increased presence of keepers.

This system is further improved to illuminate 360° (several reflectors placed in the round) or by flashes (the reflector rotates around the wick).

Burner - Chassiron Lighthouse Museum.

Burner - Chassiron Lighthouse Museum.

Example of multiple reflectors.

Hurst Castle Lighthouse Museum.

The Cape Bonavista Lighthouse operated from 1843 to 1962.

It was transformed into a provincial museum.

A rare catoptrics lighting system, made up of Argand oil lamps and parabolic mirrors of polished silver, is on display.

Oil gas and petroleum vapour.

Faced with oil problems, a new fuel was tried in the early 1880s, gas.

The first gas is coal gas. Its brightness is poor and its storage difficult because it is not very compressible.

Then comes the oil gas. The light emitted is intense. It gradually replaces the mineral oil in the light buoys.

Production plants are built in different subdivisions. When the large lighthouses are equipped with gas burners, production is done near them. The first autonomous lighthouse was Chassiron in 1895.

If the light is good, the heat is intense. You have to reduce the power, which reduces the light. Not optimum

Petroleum vapour- lighthouse of "la Vieille".

The solution will come with the placement of a sleeve on the burner. The gas will burn in it. It will become incandescent. Very nice stable light and less heat release.

Latest innovation with the use of gas, the petroleum vapour. From 1894, the lighthouse service made the first tests at the port of Saint Nazaire and at Royan. The tests were conclusive.

An Italian engineer summed up the tests: «Greater wear-saving, greater efficiency, uniform light intensity, smaller footprint, ease of use, low heat release, etc.».

The lighthouses are quickly equipped with this fuel. There will be no change before electricity arrives.

Many lighthouses still have this equipment. The explanations of the keepers (when there are still some …) make it possible to understand how it works.

Petroleum vapour - tanks.

Petroleum vapour - the burner.

Petroleum vapour - sleeves.

The petroleum vapour system consists of 3 parts.

- The first part consists of two tanks containing petroleum and two tanks of compressed air. The whole forms two similar groups.

One petroleum and air unit is connected to the other by a valve system. One unit is used and the other is in reserve.

Each tank has a pressure gauge and a pressure regulator to adjust the pressure at the burner inlet. This system is placed in the Watch room except for rotating optics.

In this case, the tanks are placed under the optics.

- The second part is the burner. Its design is a bit complex. What is certain is that it is composed of a sprinkler (or injector) and a pre-heating zone. The size of the injector will provide a more or less large oil cloud. This will measure the light emission.

- The third part is the sleeve. The most fragile part that sits on the burner.

It is composed of an impregnated cotton. During the first use, it will inflate by the oil vapour. Once inflamed, the cotton will not burn but will hold its ball shape. The steam becomes incandescent.

The sleeve is not eternal, it has a life span and it is very fragile to the touch.

The morning job is to fill the petroleum tanks.

The air tanks must also be pressurized using the manual pump.

Sprinkler control may be required.

The lamp is switched on in two steps.

The first stage is the pre-heating of the burner. A heating lamp containing alcohol to be burned is used for this.

Slide it under the burner and burn the contents.

We’re waiting for the body to warm up.

Once the temperature is set, the petroleum inlet is opened.

It vaporizes and causes a cloud to pass through the sleeve.

A flame approaches the cloud and the sleeve is ignited.

The heating lamp is then removed.

The photos are from the film "Les Gardiens du Feu" - Thierry Marchandier.

The last operation is to control the flame and adjust the petroleum flow.

If the lens is rotating or if it has rotating screens, the mechanism is started with speed control.

When the fire stops during the night, the keeper must uncork the injector with a piano wire. This manipulation is called "pinning".

To be complete on gases, mention the use of acetylene, butane and propane.

Acetylene was used at Chassiron Lighthouse between 1902 and 1905. Then, thanks to a Swedish development, it will be used for small unmanned lights. This invention makes automation easier.

Butane and propane will also be used for small fires. The advantage is the transport in cylinders or tanks. The gas is in the liquid phase, which gasifies by trigger. Two explosions occur because of carelessness of the keepers.

Acetylene burner - Hurst Castle Lighthouse Museum.

Electricity.

This latest big evolution comes with the magic of electricity.

This idea started at the same time as the application of gases. Its evolution was slower.

Arc lamp – Musée Hoek van Holland, Rotterdam.

It was already Léonor Reynaud who studied the subject. He was conquered during his visit to the South Foreland lighthouse in England. It was in 1859.

The first tests in France took place at the Sud de la Hève lighthouse in 1863. The Nord lighthouse will be in 1865.

The results are conclusive. Many benefits but sometimes a range that does not exceed the gas system.

The disadvantage is also the connection to the network, the lighthouses are often far from the network.

Independent production is being considered, but these are steam engines. It takes a lot of space to put them in. The lamps are arc.

Nevertheless, the large lighthouses are equipped with them. But slowly.

It was not until the discovery of the dynamo and its production in 1865. Better performance, lower price and reduced footprint.

The lighthouse service is chilly and wants first to amortize the purchase of steam engines. The first dynamos are installed from 1893.

Lamp of 3000 Watts/ 110 V.

The transition to electricity is very slow. The reason is the high price of modifications and equipment. At the same time, we must not forget that Fresnel lenses are also to be installed in the headlights.

The real kick-off is surely due to the extension of the public network, at least for lighthouses close to agglomerations. Lighthouse connections are less expensive. For others, generating sets require less space.

Another factor is the arrival of the incandescent lamp.

Power is, in some cases, supplied by wind generators and later by photovoltaic panels.

The lamps are available in many sizes and power. Automation will be facilitated with these lamps and many lighthouses will be equipped with automatic changers.

Collection of lamps - Museum Hoek van Holland, Rotterdam.

In the 2000s, the filament bulb was slowly replaced by an LED system.

The cost is higher but the lifetime is long and therefore requires less intervention.

A full page covers the implementation of leds in lanterns. In some cases, the lenses are removed.

Led in démonstration - Museun Hoek van Holland, Rotterdam.

Thanks.

I thank the different people who helped me to make this page.

I also thank Thierry Marchadier for his permission to extract the images from his film "les Gardiens du feu" - 1+1 Production.

Small lamp with lamp changer.

Museum Hoek van Holland, Rotterdam.

Incandescent lamp.

Museum Hoek van Holland, Rotterdam.